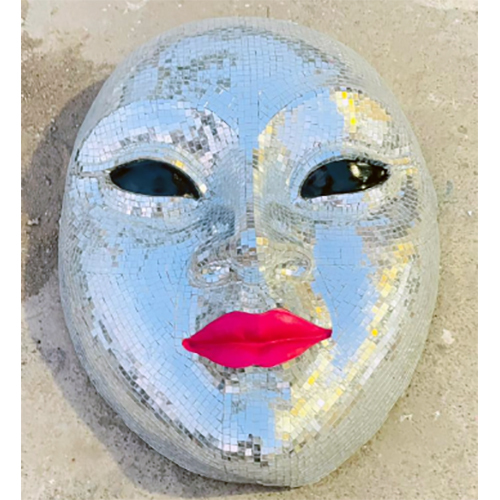

Mirror Face

Mirror Face Specification

- Crimp Frequency

- 6-12 per inch

- Staple Length

- 38 mm

- Elasticity

- Good

- Elongation

- 15-28%

- Crimp Recovery

- 65-75%

- Material

- Polyester Fiber

- Fiber Length

- 38-102 mm

- Fineness (%)

- 1.2 D

- Pattern

- Raw

- Use

- Garments, Home Textiles, Filling Material

- Feature

- Anti-Static, Shrink-Resistant, Eco-Friendly

- Cleaning Process

- Carding

- Color

- White

- Luster

- Bright

- Strength

- High Tenacity

- Application

- Spinning, Nonwoven, Padding

- Form

- Staple Fibre

- Packaging Type

- Baled

- Moisture Content

- Less than 0.8%

About Mirror Face

Mirror Face Polyester Staple Fibre is an elite, highly recommended material renowned for its radiant whiteness and uncommon luster. With high tenacity, anti-static, and shrink-resistant properties, it's perfect for spinning, nonwoven applications, padding, and filling. Offering a moisture content below 0.8% and crimp recovery between 65-75%, this eco-friendly staple fiber guarantees excellent elasticity and durability. Packaged baled for convenience, Mirror Face ensures the best price for manufacturers and suppliers across India. Highlighted for versatility, this raw fiber is ideal for garments and premium home textiles.

Mirror Face: Superior Usage & Versatile Applications

Mirror Face staple fiber is designed for elite performance in spinning, nonwoven, and padding applications. Its radiant whiteness and robust tenacity make it highly recommended for manufacturing garments and home textiles, as well as serving as a premium filling material. To maximize benefits, use standard carding processes before integration. This anti-static, eco-friendly fiber is suitable for automated or manual operations, ensuring it adapts smoothly to diverse textile industry requirements.

Domestic Market Reach, Sample Policy & Swift Delivery

Mirror Face serves the expansive Indian domestic market with uncompromising dedication. We offer flexible sample policies to help clients evaluate the fiber's uncommon quality and radiant properties before purchase. Each order is securely baled and packaged to meet industry standards. Express shipping options are available, with quotations provided promptly upon request. Our streamlined process ensures swift delivery to your location, prioritizing client satisfaction and seamless order management every step of the way.

Mirror Face: Superior Usage & Versatile Applications

Mirror Face staple fiber is designed for elite performance in spinning, nonwoven, and padding applications. Its radiant whiteness and robust tenacity make it highly recommended for manufacturing garments and home textiles, as well as serving as a premium filling material. To maximize benefits, use standard carding processes before integration. This anti-static, eco-friendly fiber is suitable for automated or manual operations, ensuring it adapts smoothly to diverse textile industry requirements.

Domestic Market Reach, Sample Policy & Swift Delivery

Mirror Face serves the expansive Indian domestic market with uncompromising dedication. We offer flexible sample policies to help clients evaluate the fiber's uncommon quality and radiant properties before purchase. Each order is securely baled and packaged to meet industry standards. Express shipping options are available, with quotations provided promptly upon request. Our streamlined process ensures swift delivery to your location, prioritizing client satisfaction and seamless order management every step of the way.

FAQ's of Mirror Face:

Q: How is Mirror Face polyester fiber typically used in textile applications?

A: Mirror Face fiber is commonly used in spinning, nonwoven processes, and as padding material. Its high tenacity, elasticity, and anti-static features make it ideal for knitting garments, producing home textiles, and providing quality filling in various products.Q: What is the recommended process before using Mirror Face fiber in production?

A: It is highly recommended to utilize standard carding techniques to clean and prepare the fiber. This ensures optimal blending, alignment, and integration within automated or manual textile manufacturing systems.Q: When can I expect delivery after placing an order for Mirror Face staple fiber?

A: Upon order confirmation and quotation agreement, Express Shipping is arranged with prompt turnaround times, usually ensuring delivery within the stipulated timeframe discussed during the order process.Q: Where is Mirror Face polyester fiber primarily supplied from?

A: Mirror Face is manufactured and supplied from India, serving a broad network of local and national clients in the textile industry.Q: What are the main benefits of choosing Mirror Face polyester staple fiber?

A: With its elite quality, high strength, radiant luster, and eco-friendly composition, Mirror Face offers excellent durability, shrink-resistance, and anti-static properties. These features deliver superior performance and value across various textile applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry